| 1. SSHE |

PTT Group companies must achieve operational goals in accordance with the safety, security, health and environment standards (SSHE) of the group in all operational dimensions. |

| 2. Operations Risk Management |

PTT Group companies must identify and manage operational risks, in order to reduce their impacts to acceptable levels (As Low As Reasonably Practicable or ALARP). |

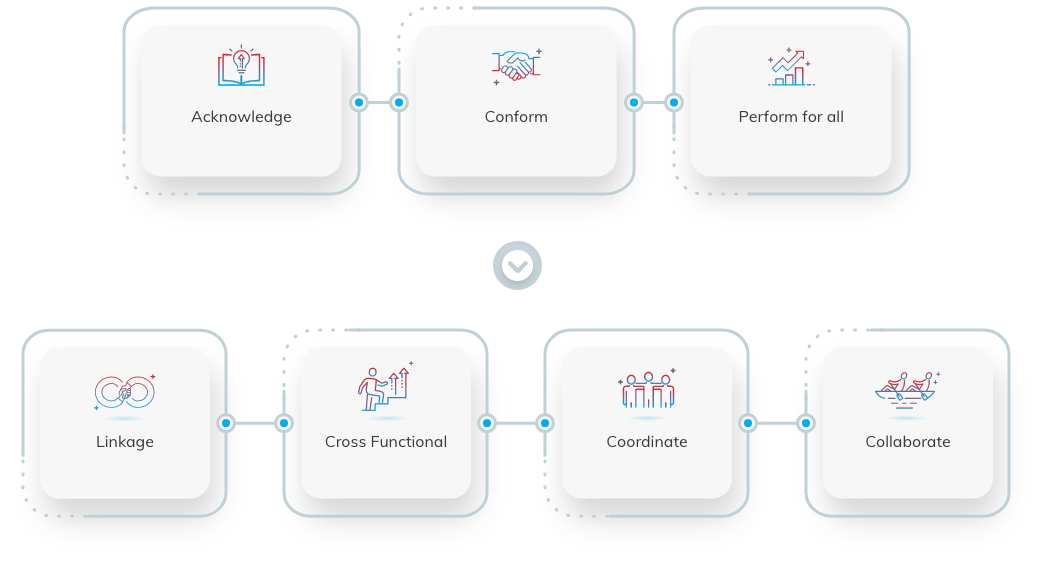

| 3. Organization & Capabilities |

PTT Group companies must possess a management structure designed to be able to make effective decisions, be able to systematically increase operational capacity, allocate knowledge and practices to increase operational efficiency continuously. |

| 4. Sustainability Management |

PTT Group companies must perform social and environmental activities, as well as foster economic growth along with communities and the society in response to stakeholders, in order to create stable and sustainable business operations. |

| 5. Reliability & Asset Integrity |

PTT Group companies must inspect equipment, machinery and utility systems systematically under the established plans and standards to create reliability, safety and reduce operating costs in every operational process. |

| 6. Operations |

PTT Group companies must operate in a safe environment to prevent injury and loss to operators and the environment. |

| 7. Value Chain Management (Downstream) |

PTT Group companies must manage their supply chain in delivering products and services that meet customer and consumer needs under efficient business management. |

| 8. Management of Contractors & Suppliers |

PTT Group companies must manage its suppliers and contractors in accordance with the established regulations, policies and standards. |

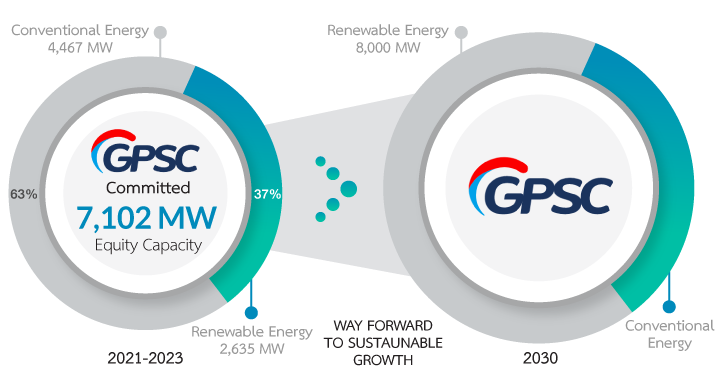

| 9. Strategy & Leadership |

PTT Group companies must operate under the safety, security and sustainability of the utmost effciency through its affiliate strategy to be the industry leader. |

| 10. Performance Management |

PTT Group companies must maintain operational leadership through assessments, benchmarks, sequences of performance, loss prevention and continual improvement. |

| 11. Capital Project Management |

PTT Group companies must manage projects through an efficient decision-making process, in order to deliver quality, safety and meet needs within specified timeframes and budgets. |

| 12. Management of Change |

PTT Group companies must manage risks from both temporary and permanent changes, organizational management or systematic operations and control these to an acceptably low level (As Low As Reasonably Practicable or ALARP). |