GRI 2-23, 308-1, 414-1

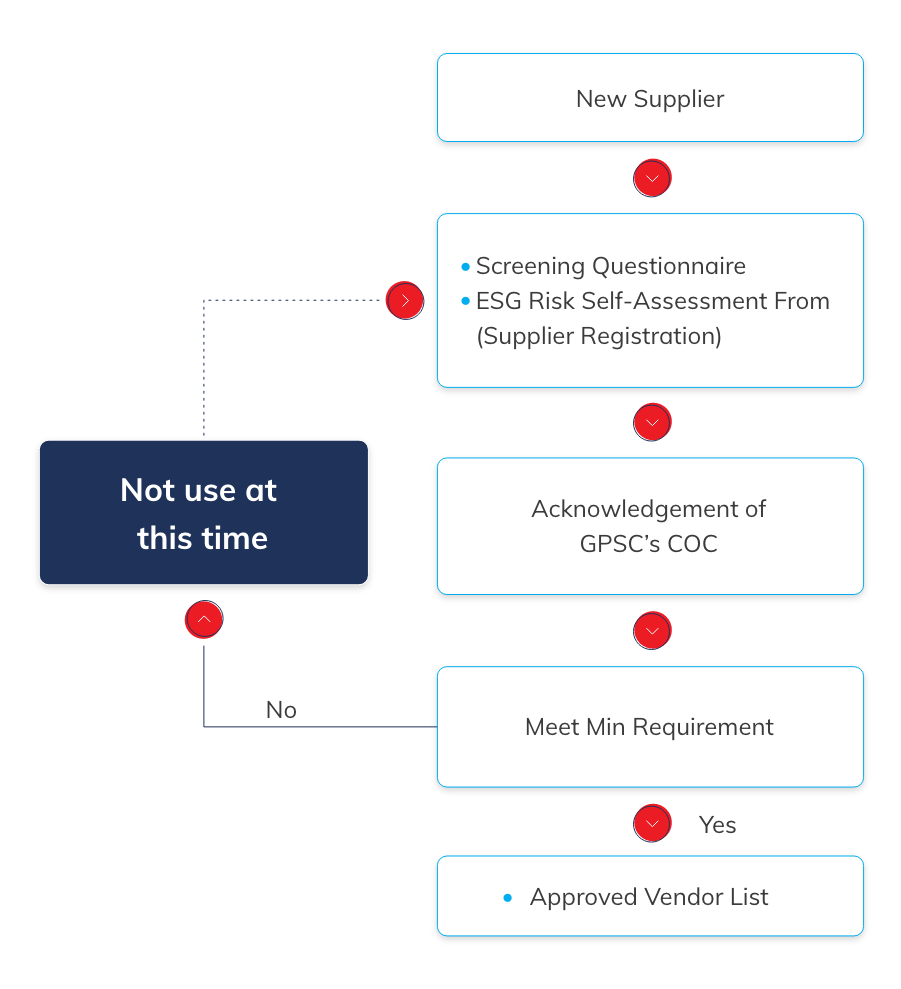

GPSC evaluates 100% suppliers using ESG assessments and overall evaluation through the supplier registration form. This will be based on the general information of the suppliers, production or service assessment, certified standards, training in security, safety, occupational health and environment management, and business operations under the principles of good corporate governance and business integrity. The supplier selection committee or supply sourcing operation officer will consider using ESG assessments with an additional supplier qualification assessment form, consisting of 6 main sections

Business (weight = 10%)

This section evaluates the business including registered capital, company history and financial status

Production (weight = 30%)

This section evaluates source of products and services, production and distribution capacities, stock and resource management

Distribution (weight = 20%)

This section evaluates distribution efficiency, time and frequency of the delivery, distribution standards

Occupational Health and Safety (OHS) (weight = 15%)

This section evaluates internal policy, management, standards on OHS issues including safety record, PPE, and quality control. By prioritizing employee well-being, adhering to safety regulations, and fostering OHS practices align with ESG focus.

After sale service & Technical support (weight = 15%)

This section evaluates support on after sale service and technical of the business and product warranty

Corporate Social Responsibility (CSR) (weight = 10%)

This section evaluates CSR policy, environmental management system and human rights. This establishes a company's commitment to ethical and sustainable practices.

Suppliers shall meet a minimum of 70% in order to get approved into GPSC Approved Vendor List (AVL)

GPSC also specifies economic, environmental, and social issues consistent with the Supplier Sustainable Code of Conduct in the General Term& Conditions. All suppliers are required to sign the acknowledgement form of GPSC Supplier Sustainable Code of Conduct to ensure compliance with the agreements and requirements.

To assess suppliers' performance, GPSC has established a supplier performance measurement procedure to be carried out with suppliers on the vendor list that deliver products or services to the company during the assessment period. The purpose of the assessment is to ensure that suppliers can deliver products and services that meet the company's needs and comply with the company's Procurement Policy.

| Evaluation Criteria |

| Score 81 - 100% |

Level A: Over expectation |

| Score 61 - 80% |

Level B: Meet requirement |

| Score 40 - 60% |

Level C: Need improvement some problems |

| Score < 40% |

Level D: Unsatisfied or Disqualified |

Suppliers shall also complete the ESG Risk Self-Assessment form for GPSC Group to pre-screen the ESG Risk level of supplier in the supplier selection process. The ESG Risk Self assessment comprises of 5 main sections. The self scoring level is considered based on the intensity of the ESG implementation in supplier’s company.

| CRITERIA |

TYPE |

EXAMPLES OF EVALUATED TOPIC |

| Company System and Policy |

Business and Governance |

- Sustainable Development Policy

- Environmental and Other Issues Communication Policy

- Privacy Protection and Cybersecurity Policy

- Anti-corruption, discrimination and harassment Policy

|

| Business Integrity |

Business and Governance |

- Sustainable Development Policy

- Environmental and Other Issues Communication Policy

- Privacy Protection and Cybersecurity Policy

- Anti-corruption, discrimination and harassment Policy

|

| Society |

Social |

- Human Rights

- Labour Relations

- Social Responsibility

|

| Occupational Health and Safety |

Social |

- Occupational Health and Safety

- Security and Emergency Preparedness

|

| Environment |

Environmental |

- Environmental Impact Assessment and Control Measures

- Work Plans / Projects to Reduce Environmental Impacts

- Environmental Training for Employees

- Environmental Performance Data collection

- Complaints, Lawsuit, or Convictions on Environmental Issues

|

After suppliers have completed their own risk assessments regarding environment, society and governance, the company We will further check the information with the selected partners to confirm its accuracy. Partners can provide information through the following channels.

- Interview at the company

- Sending information via email

- Online or telephone interviews

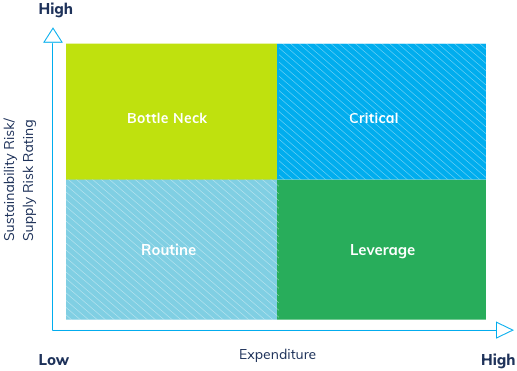

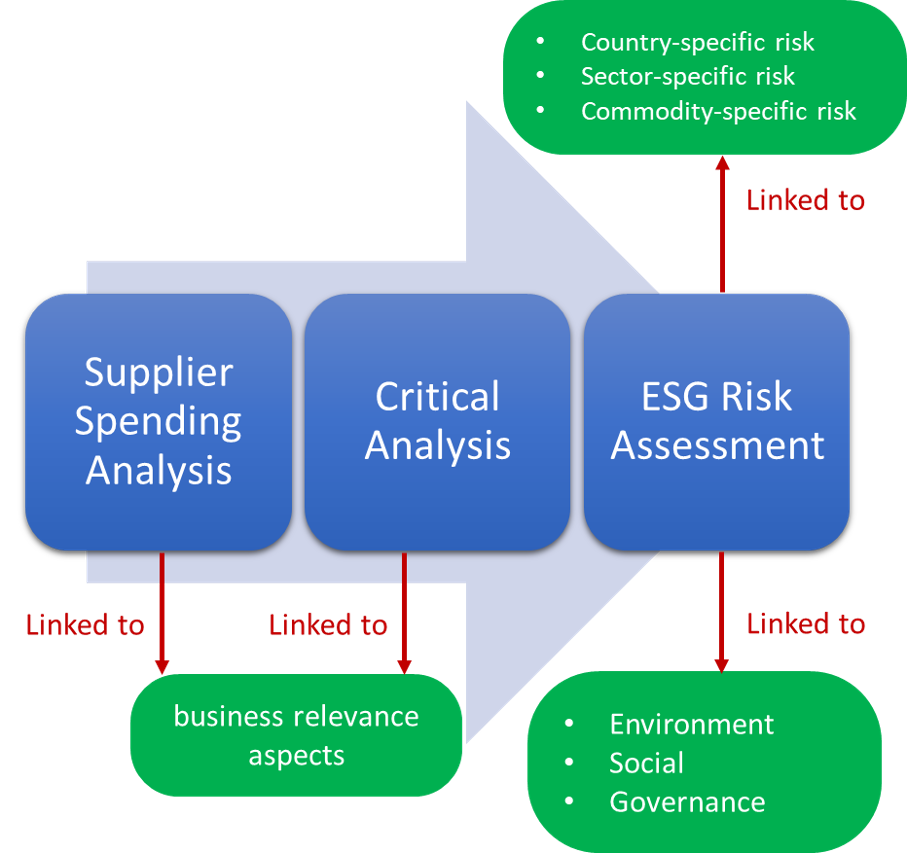

These 2 assessment tools allow supplier desk assessments with systematic verification of evidence. The 1st assessment and suppliers’ self-assessment take the form of a questionnaire. Both GPSC purchasers and suppliers are requested to evaluate and provide information and supporting evidence (if required) on the ESG policies, practices, and performance. This information is then reviewed and analyzed, to determine the supplier's business relevance and ESG performance. These assessments result in a score that reflects a systematic verification against GPSC-established specifications and requirements, considering GPSC-specific context.