- Identification of OHS risk, hazard assessments and harm in workplace

GPSC set up corporate Health Risk Assessment (HRA) which outlines as a corporate procedure for identifying, assessing, and controlling health risks within company activities and work environments. This procedure defines responsibilities for executive management, QSHE department, Human Resources team, and all employees, emphasizing hazard identification, exposure assessment, risk management, and documentation. This HRA process includes baseline, issues-based, and continuous assessments, addressing physical (such as noise, heat, and radiation), chemical, biological, and ergonomic hazards, while also stressing the importance of health surveillance and medical examinations to prevent occupational diseases

- Action plan to control, monitor and reduce harm in workplace with quantified targets

Based on the health risk assessment and occupational health and safety performance in 2024, GPSC promotes the implementation of safety regulations and continuous safety awareness among all levels of employees and contractors. This includes implementing activities to reduce occupational harm under the Here We Safe project, which focuses on site inspections for safety from the executive level, managers, and operators at the specified frequency to find and resolve risks in their areas of responsibility. GPSC has set a safety management goal and measures its performance through a clear indicator, the Total Recordable Injury Rate (TRIR). The TRIR target for 2024 is not to exceed 0.07 cases per one million working hours, and the target for 2025 is not to exceed 0.04 cases. In 2024, the actual TRIR was 0.04.

- Actions to prepare for and respond to emergency situations

In terms of emergency situations, GPSC prepares Emergency Preparedness and Response guidelines for emergency preparedness and response that aims to minimize harm to life, environment, and assets during emergencies within GPSC Group's operational areas. This guideline provides clear objectives, including providing operational guidelines for all employees during emergencies, reducing damage, saving lives, facilitating training, ensuring adequate equipment, and guiding post-incident recovery. The guideline defines various types of emergency and crisis situations (such as fire, chemical spills, bomb threats) and details a hierarchy of response organization, including roles on Emergency Director (ED), Emergency Controller (EC), On-scene Commander (OC), and also various support teams. This guideline also specifies communication protocols, equipment, and a four-level classification system for abnormal events and emergencies, ranging from minor incidents to severe disasters that require external assistance. The procedure also mandates training for all relevant departments to ensure preparedness.

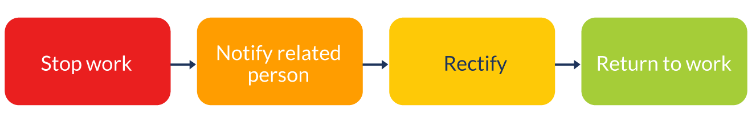

- Procedures to investigate work-related injuries, ill health, diseases and incidents

GPSC establish corporate procedure for reporting and investigating work-related injuries, ill health, diseases and incidents. This covers on acts/conditions, near misses, accidents, and abnormalities related to safety, occupational health, and environment within the company and GPSC subsidiaries. The objectives are to standardize reporting, identify root causes, implement control measures to prevent recurrence, and mitigate potential losses. The procedure covers incidents arising from employee and contractor activities both on-site and off-site work. It details a comprehensive process from initial reporting and review to incident analysis, severity assessment, root cause investigation, corrective action assignment and verification, and documentation for statistical analysis and lessons learned. The procedure also defines various types of incidents and injuries, from first-aid cases to fatalities and occupational illnesses, along with roles and responsibilities for reporting, investigating, and approving the corrective actions across different levels of GPSC management and other relevant departments. The procedure is consistent with ISO45001 standards and PTT Group guidelines for incident management and reporting.

- Evaluation of progress of the existing action plan on reducing/preventing health issues/risks against targets

The company holds monthly meetings of the Safety, Occupational Health, and Environment (SHE) Committee for both Head Office and Power Plant Sites to oversee, control, monitor, follow-up and continual improvement of the working teams in accordance with the safety and occupational health action plan. This plan encompasses legal compliance, QSHE Policy, implementation of ISO standards, and the Operation Excellence Management Systems (OEMs), with the aim of fostering a strong safety culture at work and sustainably preventing health risks and safety-related issues.

- Internal inspections

GPSC assigned internal auditors to conducts internal inspections regularly. Our internal inspections are based in ISO 9001, ISO 14001, ISO 45001, ISO 22301, and ISO 27001. The responsibility of the internal auditors are as following:

- Research on law and regulation relevant to occupational health and safety

- Review audit checklist and audit guideline

- Coordinate with functions to internal inspection

- Collect occupational health and safety-related data

- Write a occupational health and safety report and provide suggestion for improvement to functions.

GPSC internal audits are conducted in accordance with ISO 9001, ISO 14001, ISO 45001, ISO 22301 standards, and the Integrated Management System (IMS).

-

Updates on procurement and contractual requirements

Updates on procurement and contractual requirements. GPSC has the procurement and contractual requirement in the “Service Agreement” document (Confidentiality), where suppliers require to meet such requirement. This document includes the following information:

- Definitions

- Scope of Services

- Remuneration and Terms of Payment

- Form of Performance Bond

- Code of Conduct

- Form of Reports

- Personal Protective Equipment: PPE

- Safety Rule and Regulation

In addition, GPSC promotes and supports occupational safety activities, monitors occupational safety performance and employee complaints and suggestions, and uses this information to plan improvements and report to senior management. The company also requires managers to be safety role models and to conduct regular on-site inspections of occupational safety activities throughout the year.

GPSC has set an occupational health and safety goal of zero Lost-Time Injuries Frequency Rate (LTIFR). This will instill confidence in the company's operations among all stakeholders. We collects data on safety, health, and the environment, such as work-related injuries and illnesses, and incidents through the ESG Database Application. This allows for fast and accurate data management, which will be used for analysis and to determine strategies and guidelines for addressing such incidents in the future.