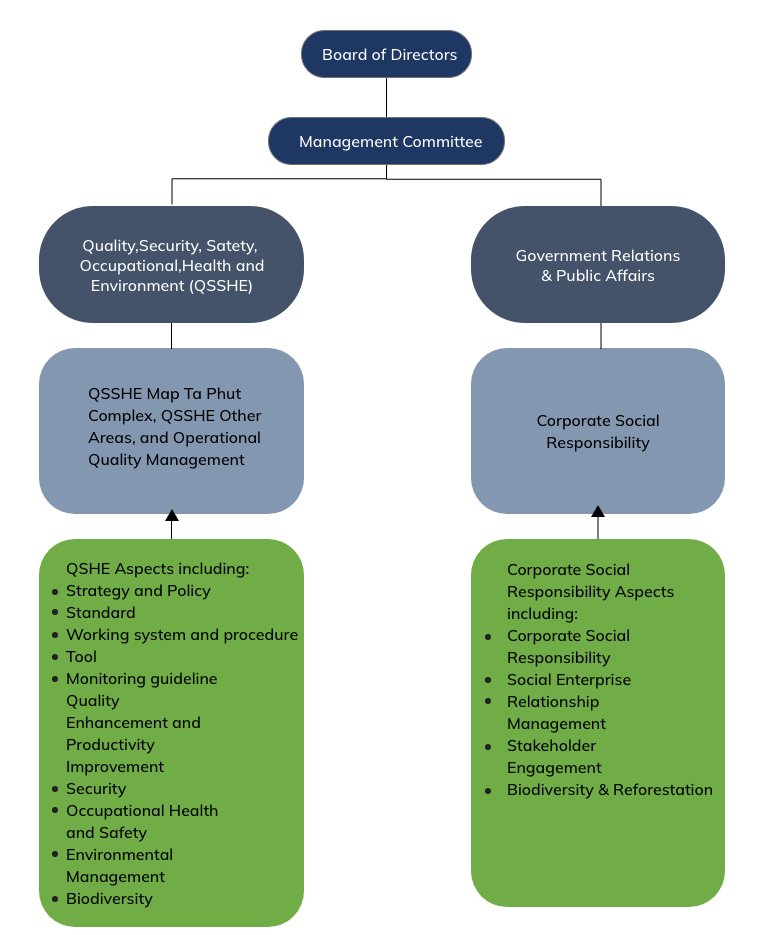

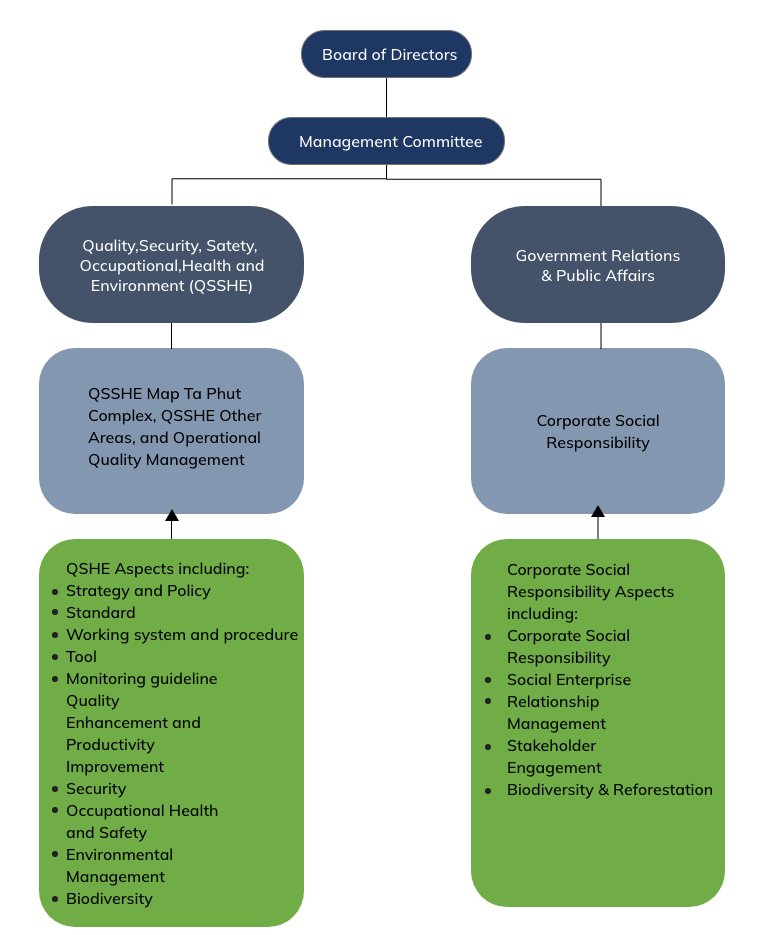

GPSC Group manages environmental performances under Quality, Security, Safety, Occupational Health and Environment (QSSHE) policy, which is under supervision by GPSC Group’s Board of Directors (BODs) and Management Committee (MC). The implementations are carried out by several departments to ensure effective implementation across the group. The overall roles and responsibilities can be summarized as follow:

Board of Directors (BOD)

Board of Directors are responsible for reviewing and approving GPSC Group' s key strategies, policies, objectives, action plans, and financial goals so that such plans are carried out in accordance with the prescribed directions and strategies. Board of Directors are taken roles to oversee the performance for Quality, Security, Safety, Health and Environment (QSHE) and the related issues including biodiversity and deforestation aspects. The performances are reported to Board of Directors for on a quarterly basis.

Management Committee (MC)

GPSC Group Management Committee is responsible for monitoring and driving of business operations in accordance with the prescribed directions and strategies as well as managing key obstacles and risks, which might affect business operations. In addition, the roles and responsibilities of MC are to provide recommendations to President and Chief Executive Officer in order to make decisions on important issues and plans as well as managing the working system with the same direction and to scrutinize the risk management of the company. From this aspects, MC takes roles to oversees and provide directions for the implementation of Quality, Security, Safety, Health and Environment (QSSHE) and the related issues in which they receive regular update on a weekly basis.

Quality, Security, Safety, Occupational Health and Environment (QSSHE)

Quality, Security, Safety, Occupational Health and Environment (QSSHE) Department has role and responsibilities for the development of standards, tools, operational guidelines related to quality, security, safety, occupational health and environment (QSSHE) as well as conveying and providing advice to GPSC Group and its subsidiaries for implementing QSSHE related aspects and policy. The responsibilities also include planning, supporting and providing support to ensure that company comply with the standards, tools, laws and regulations. QSSHE department takes role to implement several aspects at GPSC’s operations such as occupational health & personal safety, process safety and security, emergency management, productivity improvement, quality enhancement, environmental management and biodiversity-related issues. Lastly, this department takes role to disseminate measures to raise internal and external stakeholders’ awareness of QSSHE-related aspects and its impacts.

Corporate Quality Management System

Corporate Quality Management System Department is responsible for developing the policies, strategies, guidelines, standards, working procedure and tools as well as following up on the quality system across operations of GPSC Group in order to ensuring compliance with the relevant QSHE law and regulations.

Corporate Social Responsibility

Corporate Social Responsibility Department is responsible for corporate social responsibility, social enterprise implementation, managing of local stakeholders and external agencies relationship and maintain company good reputation, in accordance with GPSC Group’s strategy and direction. This department is also responsible to carry out biodiversity and reforestation initiatives in the local operations in line with company commitment.